Page Updated:- Tuesday, 24 September, 2024. |

|||||

| LIST | BREWERIES | Paul Skelton | |||

|

|

TOMSON & WOTTON'S BREWERY, RAMSGATE |

|

|||

|

RAMSGATE

FROM THE BREWING TRADE REVIEW OCTOBER 1962

TOMSON & WOTTON'S BREWERY, RAMSGATE

It is fitting that Ramsgate should be the home of the Tomson & Wotton brewery believed to be the oldest in Britain - for the Isle of Thanet is an historic corner of England. In Roman times it was separated from the Kentish mainland by the Wantsum, half a mile wide, but by 1485 this had dwindled to the present stream. However, there is still an insular patriotism which may help to explain the long history of Tomson & Wotton.

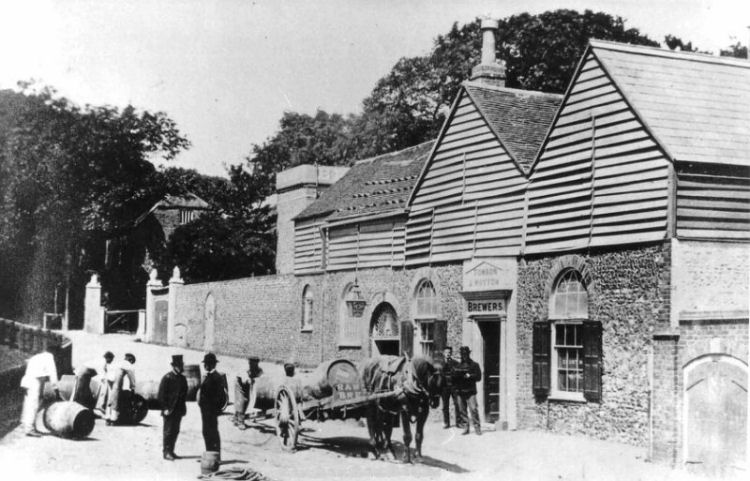

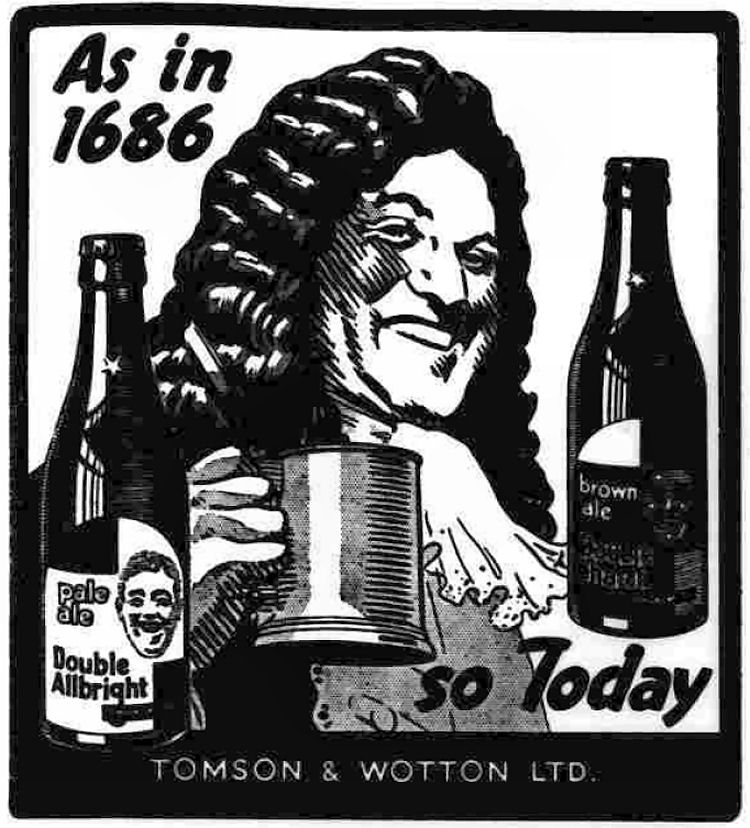

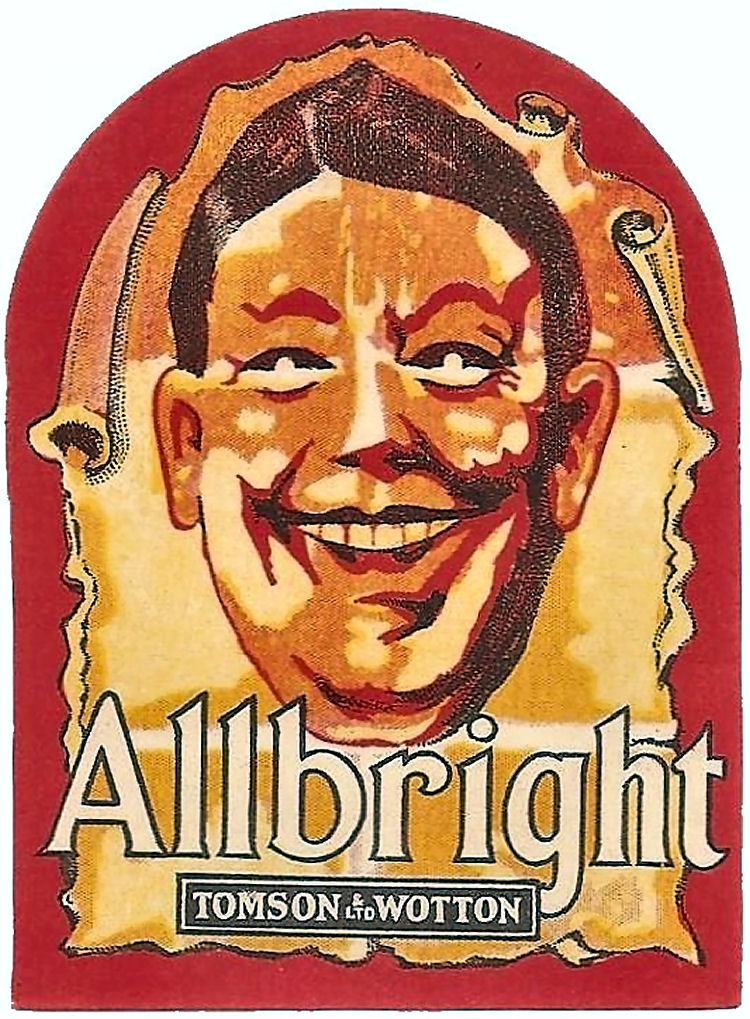

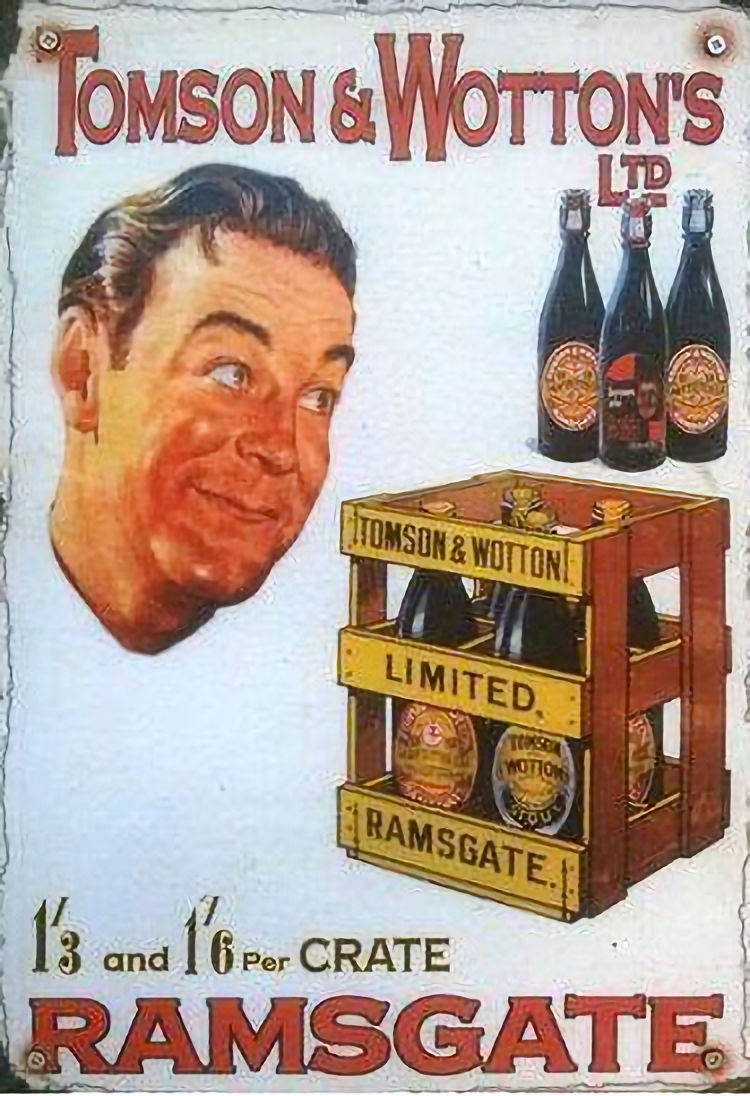

Above photo, date unknown, kindly sent by Philip Page. The Romans may have made their first English landings in Thanet: certainly Hengist and Horsa, and St. Augustine disembarked there in the fifth and sixth centuries respectively. This corner of Kent has several churches nearly a thousand years old, such as those of Minster and St. Peter's-in-Thanet, while, for the first four centuries A.D., Britain's principal port was Richborough, or Rutupiae, between Ramsgate and Sandwich. Ramsgate began as a small fishing town, In 1483 it had become a "limb" or tributary of Sandwich, associated with the Cinque Ports, Trade with Russia, which started in 1688, helped the town and in consequence the pier was enlarged. The earliest deed the brewery has dates from 1554 and refers in Latin-French to "a piece of land on the Road of Our Lord the King and Our Lady Queen." No buildings are indicated, but brewing probably started there in the reign of Queen Elizabeth I. In 1635 a deed of sale shows that Robert Sampson, Yeoman, sold his "messuage and dwelling house malthouse brew house barns stables," together with 52 acres of land, for £220. The Ramsgate brewery may be the only active one remaining from the time before beer was first taxed in 1643. In 1660 Charles II increased the tax to 2s. 6d. per barrel on strong ale, 6d. per barrel on small beer. In 1958 the tax paid was over £16 per standard barrel. Thomas Tomson bought the brewery in about 1680 and since the present Chairman, Mr. W J. Martin-Tomson, and his son are the eighth and ninth generations concerned with its management, this seems to make the trade, or private trade as it was called. Wotton was made managing partner in 1882, and under him came the brewery's greatest expansion. He was in charge until his death in 1923, at the age of 91. Mr. W. A. Wotton is a director today. In 1876 another dozen houses came to the firm with the purchase of the Ramsgate Cannon Brewery. This was closed just after the First World War. Between the two breweries there was installed a private underground telephone line - one of the first in the country. The firm's development was much helped by the coming of steamboats and railways, and when, in 1884, Ramsgate was incorporated as a borough, the gold mace was presented by Tomson & Wotton. Seven years later the concern was registered as a limited company. In 1892 brewery and plant were largely rebuilt, Further substantial alterations after the First World War made the brewery one of the best laid out in the country. Bottled beer, corked and wired in half-pints, had been brought out in 1896, but chilled and filtered bottled beer, mostly quarts and some pints, was first produced in 1905. By 1909 70 houses had been acquired by Tomson & Wotton and in those days The Shipwrights' Arms used to cellar some 60 hogsheads of Stock Bitter Ale in the spring for summer sale. Tomson & Wotton became wine and spirit merchants in 1927, and four years later its soft drink interests, which had started with the manufacture of ginger beer in 1915, were transferred to a new factory at Broadstairs and a separate subsidiary, Ozonic Ltd., was formed. The last war, when Ramsgate harbour was the main assembly point for Dunkirk's little ships, brought great difficulties, but brewing continued. The end of hostilities saw a boom in trade and the building of a modern cold room for bottled beers. In 1952, Tomson & Wotton amalgamated with Gardner & Co. Ltd., of Ash, who owned 46 tied houses, including nine in Dover. A few years later brewing ceased at Ash, except for that of the well-known Gardner's ginger beer. In 1957, the brewery entered into association with Whitbreads. There are two maltings at Ramsgate, separated from the brewery by a road, and one, which formerly supplied the Ash brewery, at Littlebourne. One of the Ramsgate maltings is now used only for barley storage and sweating. Except for specialised malt, the two active maltings supply all the requirernents of the brewery and, in addition, a large amount is made for one of the national breweries, the latter being collected by road tankers in 15 ton loads. Tomson & Wotton employ Kent barleys almost exclusively and have only once, in recent years, gone outside for this commodity. The main Ramsgate malting has considerable mechanical handling equipment and, three years ago, a Suxé burner with hopper feed was installed in place of an open fire. This burner has proved effective in keeping close control on kiln temperatures and produced considerable economies. The present malt houses at Ramsgate are 50 and 70 years old. The new one replaced the second of the two that used to abut the brewery. The kiln of one of these is now the boiler house and a cowl still surmounts the roof. Two Danks super economic boilers, one of which is about to be converted to chaingrate stoking, supply the steam requirements. Connecting with the boiler house is the mill tower and the 150-year-old mill, which has given so long a period of untroubling service and is probably the oldest piece of equipment working in the brewery, and is only now being replaced by a two high Porteus mill. Archimedean screws convey the grist to the adjacent hoppers. The brewery has its own well from which it draws water for cooling. Brewing is done from the town water supply, which is treated to remove excess carbonates, as the well water tends to be too brackish. Rain water is used to supply the boners and this is collected in underground cellars which were once used as the local cells of the town in the days when, as has been previously mentioned, Thomas Tomson was Deputy of Ramsgate, one of his duties in that capacity being to maintain law and order. In the brewhouse, which is thought to be very near its original position, the large mash tun, (shown below) with a maximum capacity of some 22 quarters, stands alongside a smaller vessel of four quarters capacity, the latter being used mainly for stout and experimental purposes. In the large vessel both a Steel's masher and copper rakes are used which the brewery considers maintain a more even temperature and give a better mashing. The large vessel was installed in 1890 and still operates as well as it did when first built.

An open coal-fired copper (shown below) is used in conjunction with the main mush-tun. The brewing staff consisting of Mr. A. Fearn, Head brewer, and Mr. T. M. Wilson, express a definite preference for this type of copper, as opposed to the steam-heated variety, and have no difficulty in obtaining a temperature of 214° F. even though it is an open vessel. A smaller closed copper is situated alongside the larger one and this is used with the small mash tun and acts as a reserve for the other.

A hop store is situated conveniently adjacent to the brewhouse, but the main hop storage is contained in a building at the other end of the brewery. This building at one time bore one of the old fire plaques, which denoted to the fire brigades of those days, who were employed privately by insurance companies, whether or not they should put out a fire in the building. Other equipment in the brewhouse consists of a cast-iron hop-back (shown below) which was made wider than is now normal in order to fit in with the other vessels, and a paraflow installed originally in 1926, and believed to be one of the first in the country. The original installation had a limited capacity and tended to create a rather long working day for the brewing staff. Consequently, after the war, another section was added which reduced working time considerably.

The spent grains from the mash tuns used to be removed by simply shovelling them into the side of the old boiler room. This had to be reconstructed as buildings erected after the installation of the original boilers prevented the new ones from being conveyed into the heart of the brewery. Because of this, another method had to be found of transporting the spent grains from the brewhouse and it was found that by re-wetting the, grains in the mash tun they could be pumped through pipes, by means of a centrifugal pump, to a place outside the brewhouse where they could be conveniently collected by vehicles. In the fermenting room most of the 14 vessels are wooden, constructed from the now-unobtainable Kauri pine. In consequence any repairs or alterations to be effected have to be carried out with a South American wood of similar characteristics. In fact this has been done here in dividing one large vessel into two smaller ones. One new vessel has been made of oak. All the wooden vessels are unlined, Three aluminium vessels and one of glass-lined steel are also available but are used mostly for the enlarged trade during the summer months. The sizes of the vessels vary in capacity from 15 barrels to 90 barrels, usually in multiples of 15 barrels. A slate settler is used for most of the brews coming from the fermenting vessels. The yeast room is conveniently situated under the fermenting room. The Scott yeast system is in operation and the yeast is drawn into a new 10 barrel stainless-steel receiver and then blown through one of the two Johnson presses. Also in the yeast room are the three tanks used for the maturing of "Cavalier," the company's strong bottled pale ale, which normally gets a Fortnight's storage in this cool place before going to the cold room. There are also two small storage vessels and the large tank used for transferring light ale to the cold room. A refrigerated yeast store is fitted into a corner of the cold room and has a door opening into the brewhouse. The casks used in Tomson & Wotton's brewery are all wooden with the exception of those used for the small amount of keg beer produced. A cooper is employed for the repair and maintenance of casks, all new ones being made by an outside company. There is quite a large cask-washing shed, at one time a malting floor, where 60 casks an hour are dealt with by a Hopkins Nulli Secundus washer before being examined and rolled to a nearby room for dry-hopping, corking and stencilling. The racking room (shown below) next to this is a fine large and lofty room with dormer windows and the four types of draught beer are racked from a Morton three-cock racker. This room is partly below ground level and from it run cellars and tunnels under the road to large cellars near the maltings which were used for beer storage some half a century ago. The cellar directly under the malting is now sealed off to act as storage for the wine and spirit department. The casks having been topped, and in most cases fined, are finally raised by a hoist to the adjacent loading stage which has four bays.

Immediately after the last war, construction was started on a new cold room on the site of the old boiler house. This now contains seven 30-barrel tanks and two smaller ones and deals with the two pale ales, the stout and the barley wine which is first matured for six to eight weeks in cask. The two brown ales, of which the sweeter "Tom Brown," has recently become an exceptionally large seller, pass through two Pontifex quick chillers. The bottling hall has two 300 dozen per hour filling lines. The washers are Miller Hydros, the one with automatic unload having been installed this year. The fillers are 24-head Pontifex machines and they are coupled with 8-head Jumbo crowners. An unusual feature of the layout lies in the fact that both lines feed into one 600 dozen per hour Briggs steam-vapour pasteuriser which has a low partition above the continuous conveyor. The bottles diverge at the outlet end of the pasteuriser into two Banks Labellers. Guinness is received by tanker and fed into two 30 barrel storage vessels Shown below) for bottling. There is a substantial storage area for full bottles and crates but at Christmas, and at the height of the summer season which is the main peak, every bit of space is used.

The office block was built about 1890 and is no longer adequate in size, especially since the amalgamation with Gardners. In consequence, the first stage in a programme of expansion and alteration is about to begin and it is hoped that in a few years' time it will be possible to accommodate nearly all the brewery's personnel in the one place since many of them are at present housed in a building up the road. One of the most noticeable features of this long-established brewery is the compactness and convenience of the layout. Nearly all the processes adjoin the ones preceding and following them and careful planning has thus gained ease of cleanliness and savings in handling that greatly contribute to the well-being of a seaside brewery like Tomson & Wotton who have to supply such a fluctuating seasonal trade. Over 40 of their houses are situated in Ramsgate, but some are as far afield as Hythe in one direction and Whitstable in the other. Tomson & Wotton pride themselves on the houses they own. A lot of time, trouble and expense have obviously been employed to ensure their attractiveness. The Cinque Ports Arms in the centre of Ramsgate was rebuilt last year in contemporary style and the nearby Horse & Groom was completely renovated in traditional manner a year before. Perhaps this symbolises a company trying to get the best out of both old and new ideas.

|

|||||

|

If anyone should have any further information, or indeed any pictures or photographs of the above licensed premises, please email:-

|

|||||

| TOP |

|

|

|||